The 5-Minute Rule for Sheroz Earthworks

The 5-Minute Rule for Sheroz Earthworks

Blog Article

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Table of ContentsHow Sheroz Earthworks can Save You Time, Stress, and Money.Sheroz Earthworks Things To Know Before You Get ThisThe smart Trick of Sheroz Earthworks That Nobody is DiscussingSheroz Earthworks Fundamentals ExplainedGetting The Sheroz Earthworks To Work

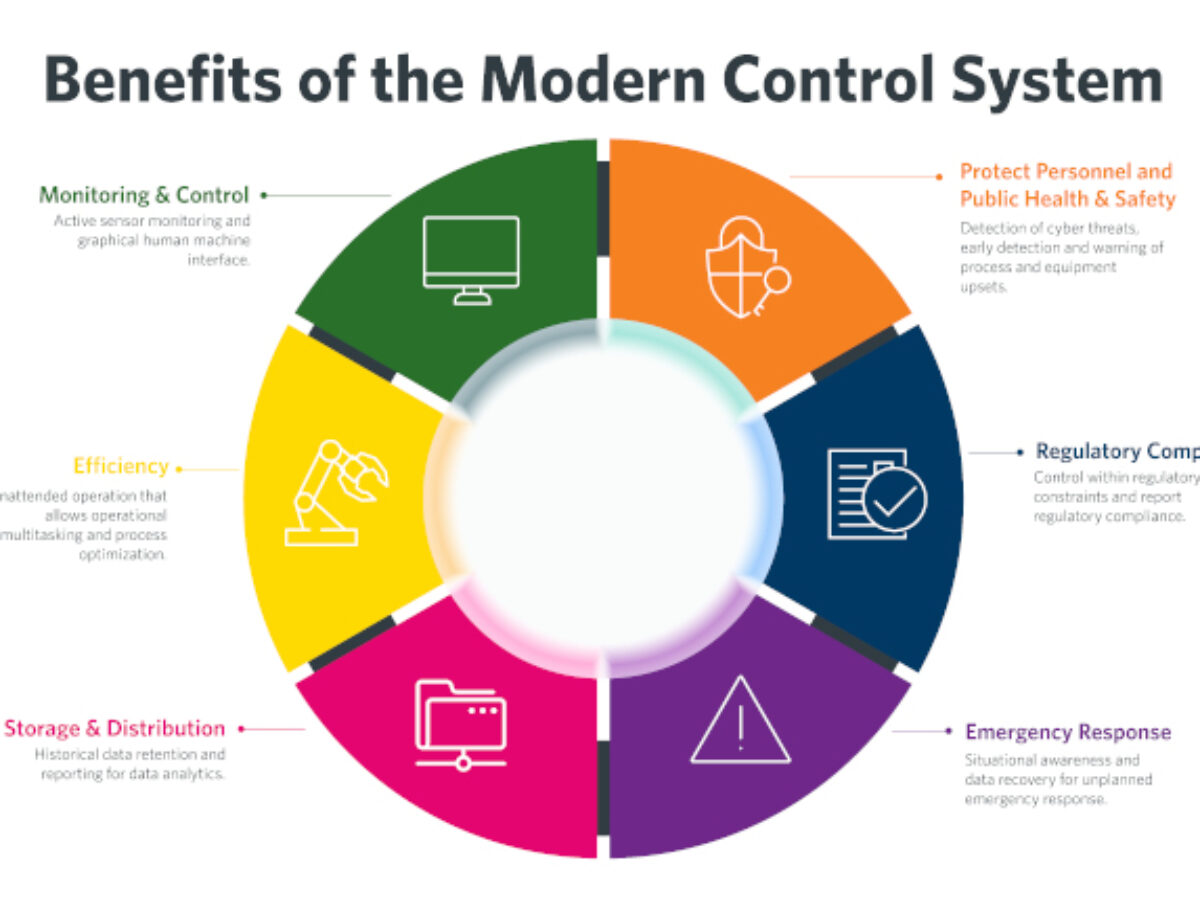

For any type of earthwork professional, it is important to carry out collaborate with top quality, precision, and on time. Using equipment control in job makers enables enhancing the different stages in the earthwork process, from preparing to the upkeep stage - trimble parts. The maker control system helps the device operator in attaining the target plane swiftly and quickly

The device control system overviews the operator with centimeter accuracy. With Xsite PRO 3D, you'll constantly understand specifically just how much to cut or load. Your local Xsite technological support can direct you and assist with any type of issues without checking out the site. Remote assistance saves money and time, as it reduces downtime in jobsites.

The Ultimate Guide To Sheroz Earthworks

Our system's parts are meticulously designed to stand up to the rough conditions of building and construction websites. Comparison of the exact same project carried out using maker control versus the typical approach discloses that, on average, the standard strategy needs 50% even more time to achieve the same job as the technology-assisted approach.

Appears great, ideal? Enter the Xsite equipment control system; it's below to supply you with a considerable advantage when functioning with earthmoving machinery. Discover exactly how Xsite Maker Control can boost your productivity and make sure job safety! We comprehend that learning a new modern technology could seem like a drag, yet don't worry! Our friendly and specialist neighborhood support services have actually obtained you covered, ensuring that you can keep functioning smarter without disruptions while on the work! With remote assistance, your local Xsite dealership can offer assistance or troubleshooting without having to visit the website! What sort of excavators does maker control fit? Xsite Machine Control systems can be mounted to any excavator from mini excavators to large mining excavators.

Just how does machine control job? In 2D systems, the device is equipped with calibrated disposition sensing units. These sensing units are placed on the pre-determined parts of the equipment in excavators the sensor are normally installed to the framework, boom (or booms), miner arm and to the quick coupler - topcon laser levels. By making use of the information received from these sensors the system can determine the specific placement of the excavators container pointer in significance to a recommendation point.

The system is really simple to learn the basics can be educated in under one hour of training. How does the remote assistance job? A wireless web connection makes it possible to establish a remote link in between the equipment control system and the service.

The Best Strategy To Use For Sheroz Earthworks

Xsite Device Control systems support open standard file styles, enabling smooth information flow from one system to another. Depending on your choice of system (with or without positioning, i.e., 2D or 3D), your maker is furnished with disposition sensing units, a controller unit, and a display/operating panel.

Many hardware and software application remedies exist to assist figure out a maker's current position on the earth and contrast it with a preferred style surfaceand construction operators can do even more to utilize the benefits. Equipment control is using various placing sensing units and a screen to supply the operator with a referral between the placement of the bucket or blade and the target grade.

Depending upon the setup, device control systems can give the driver with a simple aesthetic overview to pail or blade placement, or can immediately move the blade to quality by speaking with the maker's hydraulics - https://sitereport.netcraft.com/?url=https://sheroz.com.au. There are device control systems available for almost any kind of device: , dozers, excavators, dirt pop over here and asphalt compactors, scrapes, trimmers, crushing machines, and pavers

Unknown Facts About Sheroz Earthworks

Some benefits include decreased rework, boosted task efficiency, and reduced checking expenses. Device control can also aid raise performance and reduce total prices. This technology is altering the way the building market works. Construction tools without maker control will certainly end up being a distant memory and the benefits got from it will certainly be many.

Trimble maker control systems offer a myriad of benefits to any individual that uses earthwork equipment and, at EarthCalc, we can provide you with 3D apply for your device control-enable devices. Not exactly sure if maker control deserves the expense? Think about the adhering to factors why you need to consider this choice.

Utilizing GPS lined up with your 3D layout data, these systems virtually ensure that you will get rid of or position the correct quantity of material at the building website. On many building sites, revamp is a common and irritating fact, yet with Trimble machine control, you can get rid of the need for rework.

Sheroz Earthworks - The Facts

Often, with Trimble machine control, you can get rid of excess tools at a details task site. A job that might have required the use of 3 or four pieces of excavating tools now might require only two pieces of tools to achieve the very same task in much less time. This permits you to move your tools to an additional work website and manage multiple work at once.

Report this page